This article is meant to inform customers of the purpose of a wiring harness for a telescopic seating system.

A Critical Component For Bleachers

For many customers, telescopic bleachers are simple in nature: they open and they close. However, Farnham Equipment Company (FEC) often serves as educators to broaden a customers understanding of everything that consists in a telescopic seating system. While the main purpose of the bleachers are to effectively open, close and provide seating, the understructure and what makes it operable or inoperable is far from that simple. This is one reason why FEC inspections yield such valuable information, as the level of depth covered in these inspections provides customers with the clearest picture of the state of their equipment.

The wiring harness is a critical component that is connected with the operating systems and control systems. While there are several factors that go into when a customer should consider replacing this part, the main factor, like many FEC inspected items in inspections, comes back to customer safety. A couple of signs that may signal the time to replace the wiring harness include:

- Dry, rotted, or frayed wires

- Bare wires exposed

Many customers are not familiar with the wiring harness, so FEC crafted a Q&A style guide to answer the main questions a customer may ask.

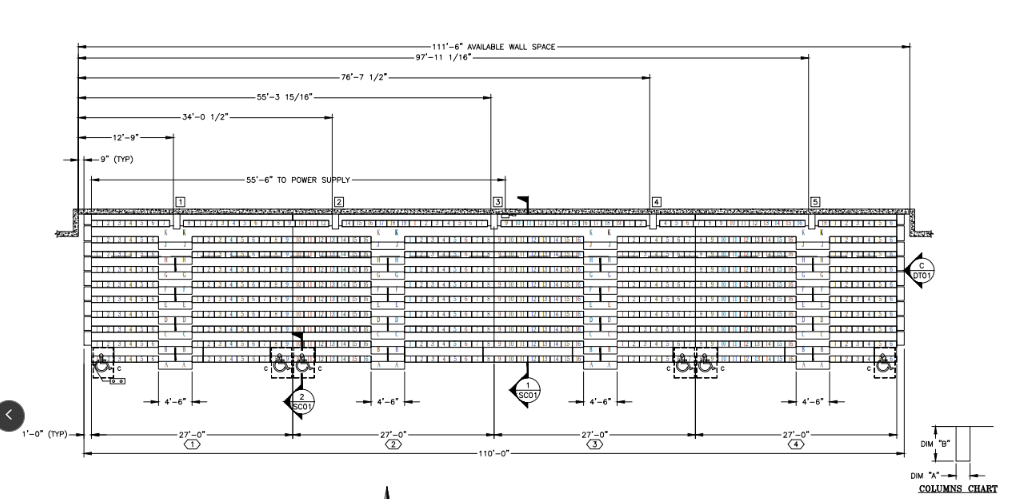

Q: What does a wiring harness look like, and where is it located?

A: Below are some photos of a what the harness looks like. As for location, it is located underneath the bleachers, in between the frame wheels.

Q: Are wiring harnesses covered in an FEC inspection?

A: Yes, the FEC inspections are comprehensive nature and wiring harnesses are included in a typical FEC Inspection (line item #41)

Q: How long does a typical wiring harness last before it needs to be replaced?

A: That answer depends on a number of factors. For instance, the life span may be shortened if there are pinch points that are caught in the opening and closing of the bleacher system. Additionally, if students are able to get underneath the bleachers, there could be instances where they pull on the harness, causing damage to it. Conditions of the gymnasium may lead to quicker or slower fraying of the wiring. As a general rule of thumb, it’s likely a customer would replace their harness during the lifecycle of the bleacher system.

Q: Are there any advantages that come from just replacing a wiring harness?

A: Besides ensuring safety for patrons and spectators, if the conditions allow, replacing a wiring harness is a substantial savings compared to replacing the entire power system. While the wiring harness is often lumped together with the power system and the control system, it is not always necessary to do a large replacement of all of these parts. Having qualified personnel give you a proper assessment of these items through inspections would be the best way to identify what options a facility has for extending the life cycle of the bleachers.

Q: What are the risks of not replacing a wiring harness?

A: Safety is FEC’s number one priority when it advocates for repairs, upgrades or preventative maintenance. In the case of a wiring harness, having frayed or bare wires can lead to a shock hazard for anyone who makes contact with the harness. Additionally, the operation of the bleacher system will be impacted if the harness is faulty and not properly addressed.

Q: Do you have photos of a wiring harness that would require replacement?

A: Sure do! Thanks to the FEC Inspection App, there are several inspections performed that have cited wiring harnesses needing replaced. Below are some photos to give customers an idea of what state of the harness would merit a replacement.